If you really think about it, a steel string acoustic guitar is trying to break itself from the first time you string it up. It’s two pieces of wood (a body and a neck) that are glued together with metal strings tied to the opposite ends of both pieces. When you tighten those strings up to pitch, they put over 150 lbs of pressure on that glue joint; extrapolate that over 20 or 30 years and it makes sense that the wood gets compressed and shifts position a little. The result is that the neck angle changes and string action slowly gets higher and higher. So as techs, we chase that changing angle by lowering the saddle a bit every time we set it up. Eventually we run out of saddle material and need to reset the neck angle.

When an older guitar like this 1974 Gibson Dove comes into our shop with high action, we make sure to check the neck angle with a steel straight edge (above.) We would like to see the steel pointing over the top of the bridge rather than touching it. So this is a candidate for a neck reset. We will steam off the entire neck, reshape the dovetail joint that holds it in the body, and reglue it.

By injecting steam into the dovetail joint, we can loosen the glue and remove the neck.

Here’s Dan shaping the neck angle by pulling sandpaper through the neck heel area. This is how precise this work has to be; he counts how many times he pulls sandpaper through each side of the neck. We’re talking thousandths of an inch. Once he’s pretty sure he’s got it right, Dan double checks the neck angle with the straight edge…

When the angle is correct, the neck is reglued to the body and clamped into place. Handmade clamping cauls protect the body and the fretboard from the pressure of the clamps.

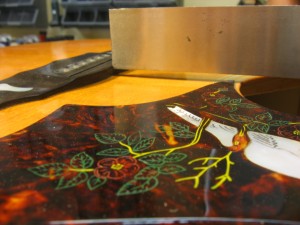

After the glue sets and the clamps are removed, there’s some work to be done to the guitar’s appearance. At the factory, Gibson guitars are painted after the neck and body are joined together so the finish has to be scored when we remove the neck. This means we will need to do some touch up in our spray painting booth after it’s glued back on.

Now that the neck angle is correct and the repair is invisible, we can move on to making the guitar play right. Most of the time when we reset a neck, we need to also level and refret the guitar to get optimal playability. That was the case with this Dove as well. We’ll be posting photos of the refret process in a separate blog.

Now this beautiful old guitar has low, comfortable action; new frets; and many more years of great sound ahead of it.

THATS MY GUITAR and to all who have a “classic” and are worried about getting any work done on it – rest assured the guys at ChicagoFretworks are truly masters! They called me at every step to give me an update and in the end this old Dove plays better than when I first purchased it over 30 years ago. I highly recommend them to all considering work on your “baby!”

Been asking around about my Mom’s 55 J45 . Had James Fry put a new bone bridge in , set the intonation, add buffalo pins and get the angle correct. Ad the new tuner knobs to existing tuners gears. He said he noticed he did not like the angle of the neck. Previously I had a luthier from Larrivee reset the neck. Looks like it did not get done correctly. My question is, can another reset be done? James Fry is a very good luthier and he says , to be carefull , there is a lot of trama to the 55 and does not want to do it, He would refret first. I just want another opinion. This guitar has been in the family and we have been the only owners. Its been to Nashville , CBC in Toronto and many years on the Canadian Country music scene. Your advice and comments would be appreciated. Dave from Calgary Alberta

can you out same foto of the first part of making guitar and send me some informaigion please

How did you cut that chunk of spruce under the tongue when steaming off the neck? I’ve read about Gibsons with this type of joint but I’ve never seen one removed.

Nothing unusual Greg. That block (actually made of maple) is part of the neck joint and any glue inside that area came loose either with the fingerboard heat or the steam. At any rate, it didn’t take any particular magic to it out.

Where do I find finger board for 1964 dove guitar.

Depends on what you require Sharon. A fingerboard from an actual 1964 Dove? You’ll have to get very lucky watching eBay probably. But if you’re ok with the idea of a replacement fingerboard with the correct looking inlays, that can be made by a skilled luthier. We get most of our supplies for projects like that from Stewart MacDonald and Luthiers Mercantile.